Dental laboratories used many materials to fabricate dentures and partials, but a digital manufacturing process didn’t exist. Marks worked with a materials manufacturer to develop a method for 3D printing using their materials. Per Marks, there are many advantages to employing a digital workflow for full and partial dentures, including:

-

Facilitating faster and more collaborative communication between technician and prescribing dentist

-

Increasing precision with the digital design and reducing finishing and fitting efforts once processed

-

Improving esthetics and occlusion as a result of customization opportunities for replacement teeth

-

Streamlining tooth arrangement and grinding needed for contacts and occlusion

-

Reducing the denture fabrication time by eliminating the model duplication, hand-waxing, flashing, boil out and injection molding steps used in traditional fabrication processes

-

Decreasing material costs resulting from streamlined processes that no longer necessitate grinding or residual losses of material in the milling blank.

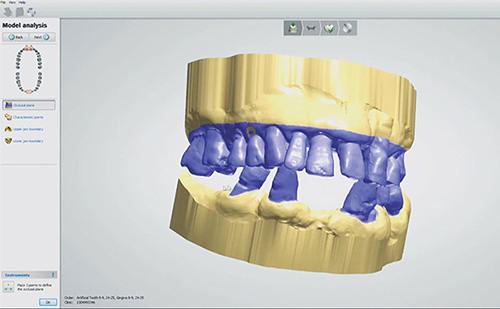

The Journal of Prosthodontic Research published a case report last year that details how an intraoral scanner can get the necessary detail needed for a digital denture fabrication workfow.1 Using a scan retractor, the clinician was able to retract the lip, cheek and vestibule tissue effectively on a 60-year-old man’s maxillary complete denture. The interocclusal record was also scanned, providing a digital vertical dimension on which to build the denture base and teeth. Then the team was able to create a customized denture that optimized the patient’s occlusion through an entirely digital workflow.

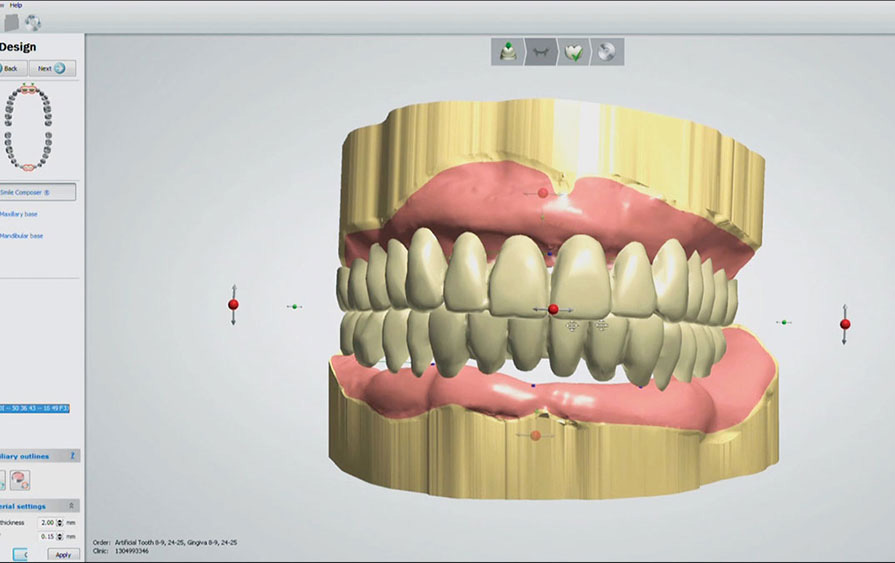

Gall also doesn’t have experience producing digital dentures yet but recognizes it would have some advantages over conventional fabrication, especially for predictability. Dentists, patients and technicians have a chance to see and make adjustments to the dentures before they’re even made. Conventional fabrication has a lot of trial and error associated with it from choosing a mold shape to tooth size to color and any number of other details.

“You have the denture on the screen in color and now you have the option to pick a mold of the tooth virtually that fits the patient. So if they want the teeth longer, more rounded, more squared or any other detail of the anatomy, all of those things are a couple of clicks away with a mouse,” Gall explains. “You can make huge changes easily in comparison to going through a shade and mold guide and guessing, then having multiple set-up try-ins and multiple office visits.”