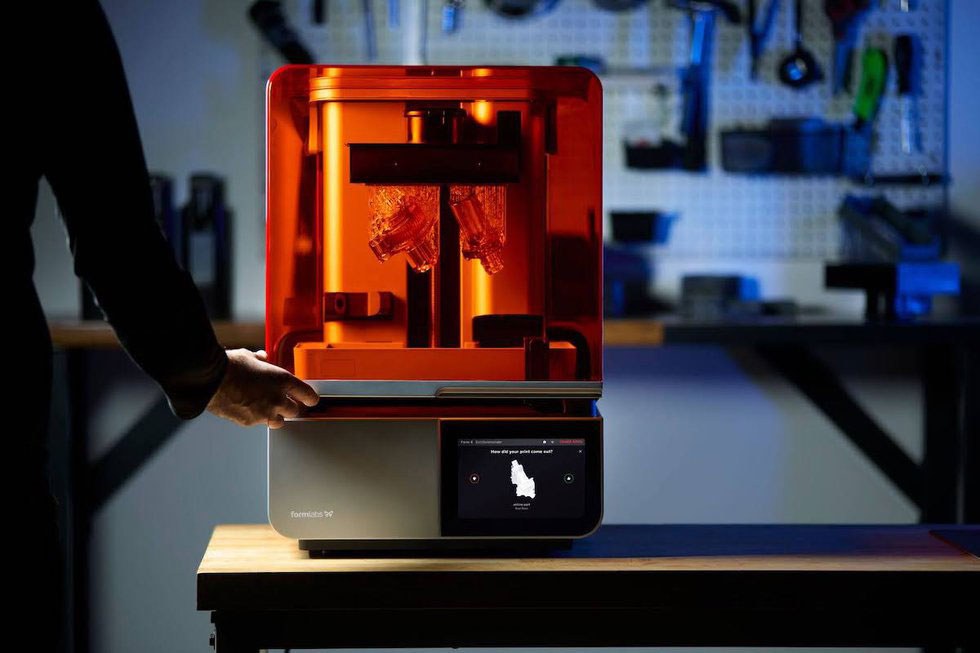

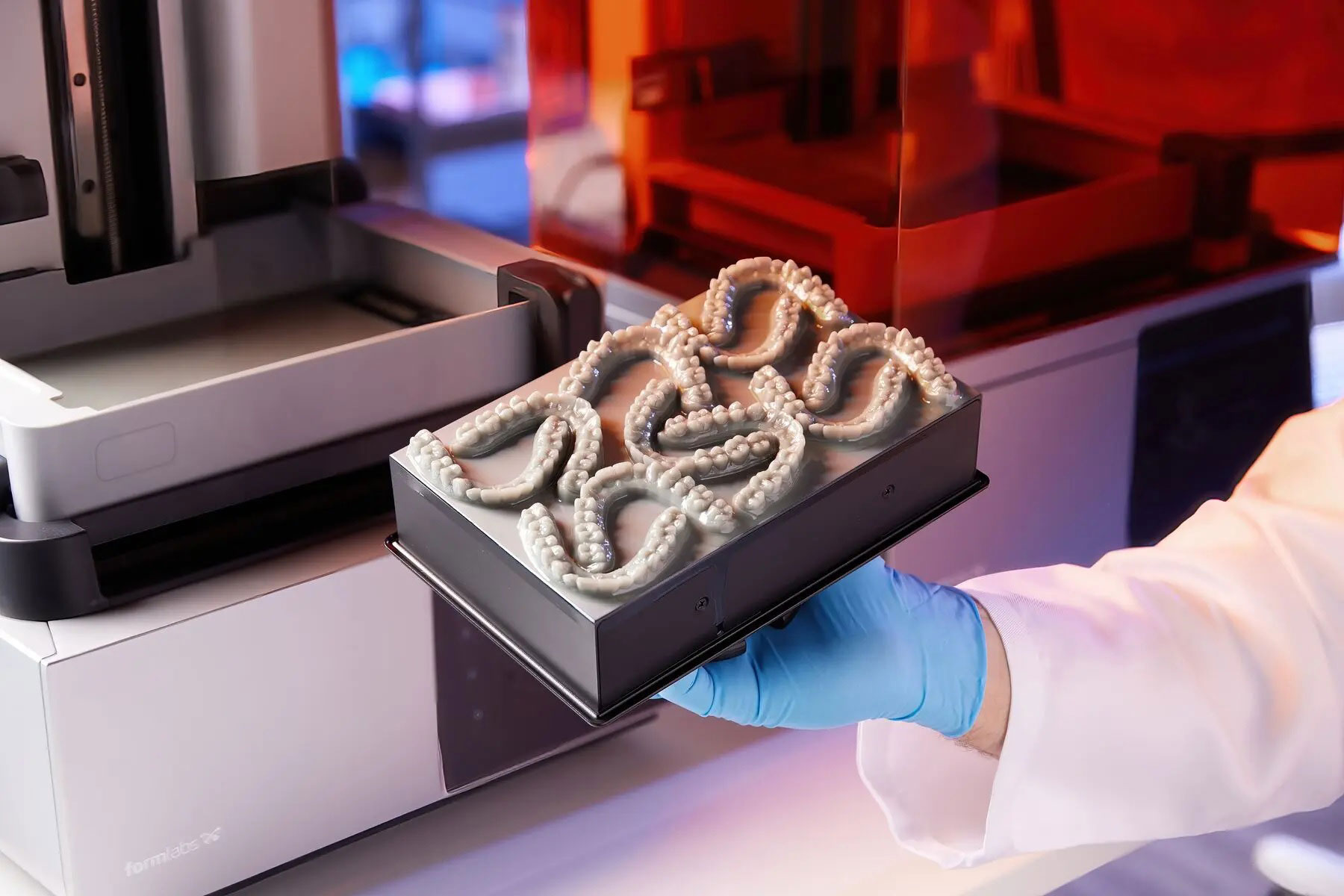

Unveiled today, Formlabs’ new Form 4 and Form 4B 3D printers promise faster print speeds designed to provide professionals new levels of productivity. The Form 4B can reportedly print an accurate, great-fitting dental model every 49 seconds.

The company’s new flagship resin 3D printers look to set a new standard for additive manufacturing with Formlabs’ proprietary new Low Force Display (LFD) print engine, updates to their library of industry-leading resins, new automated post-processing, and an enhanced user experience. The Form 4 printers are said to deliver 5 times faster print speeds to enable new levels of productivity for healthcare professionals as well as product designers, engineers, and manufacturers. The result: prototyping through production that can lead to fast reliable parts and an accelerated time to market.

The company has also expanded its resin library including the introduction of new resins for orthodontic and dental models.

The Form 4 printer benefits include:

- Fast print speeds: Prints 2 to 5 times faster than Form 3+ depending on material, enabling same-hour iteration or batch production with masked stereolithography (mSLA) technology.

- Completes most prints in under 2 hours and small parts in minutes of cycle time.

- Achieve maximum vertical print speeds of 100 mm per hour.

- LFD print engine: A departure from laser and galvanometer technology, the new printer features an ultra-high power backlight (16 mw/cm2), proprietary release texture, Light Processing Unit 4 (LPU 4), and dual-layer, flexible film resin tank.

- Unmatched reliability: Validated print settings, precision heating, force sensing, and debris detection produce print success.

- Stunning parts that always fit: With 50-micron pixels, highly collimated light, advanced pixel smoothing, and light touch supports, the print quality is strong.

- Intuitive to use: Users can learn to print in 15 minutes – featuring automatic resin handling, instant material changes, automated post-processing, and quick release build platform technology.

- 40% lower cost per part: Delivers affordability with long-lasting resin tanks (75,000+ layers) and Light Processing Unit (1M+ layers), 33% lower resin pricing, 30% larger print volume, and 3.5 times higher throughput, the company states.

New Resins

In addition to the new printers, Formlabs is introducing 6 new resins to its resin library, including model resins for orthodontic models and dental models. These additions are the Fast Model Resin, for high-speed prototypes and production of orthodontic models; the Precision Model Resin, for highly accurate dental models that always fit; and 4 newly reformulated General Purpose Resins designed to take advantage of the Form 4 ecosystem to print 2 to 5 times faster than Form 3 with improved toughness and color.

The Form 4B, designed for innovative healthcare professionals in the dental and medical industries, is compatible with 15 additional biocompatible materials. The Form 4, meanwhile, is validated to use 17+ other performance materials from Formlabs’ materials library. The company plans to regularly add new materials.