One of the longest-standing issues in dentistry is crowns that do not fit. Making a crown fit perfectly between adjacent teeth is hard work. The problem is knowing exactly where the contact point is located to make the adjustment. Guessing or eyeballing to adjust the crown is time consuming and does not guarantee a good—let alone perfect—fit. A poorly fitting crown is very uncomfortable and could be problematic for the patient. And an unsatisfied patient could be problematic for you.

Certain methods have been developed to combat poorly fitting crowns, mostly by means of marking the interproximal surface to determine where to adjust. For example, fitting a piece of articulation film in between metal forceps (or just holding it with fingers) is a pretty popular way to mark the interproximal surface. Marking floss and contact paint are also tools used to mark the interproximal surface for adjustments. All of these methods make it difficult to see when positioning the product, plus they are messy and inaccurate. Again, getting a crown to fit perfectly is hard work.

It was out of necessity that a dentist from Boston came up with a new idea. His solution, presented to Microcopy, could eliminate the problems caused by guessing and checking and other methods of marking the interproximal surface. That solution has been developed into Proxi-Chek. The basic design of Proxi-Chek was inspired by another product of Microcopy’s, Bite-Chek Articulation Film. Essentially, the idea behind both products is articulation film with an easy-grip handle. The initial concept of Proxi-Chek was presented to us in the form of a coffee stirrer. This dentist had finally created a way to ensure a perfect fitting crown. He had created a marking device that was designed to be simple. We now had an opportunity to completely change the way dentists thought about marking along the interproximal surface. Now, it could be quick and easy, significantly cutting the time to adjust crowns. Based on the results, we decided to pursue this project.

Even before the first prototypes of Proxi-Chek were developed, the idea behind it was well received by dentists. However, Proxi-Chek met most of its praise during the testing phases. Dentists were impressed by the ease of locating the contact point and the decreased time spent fitting the crown. That was the goal; to make the process of adjusting crowns easier while also fulfilling Microcopy’s mission to provide exceptional innovations for safe and simple dentistry. As the development of Proxi-Chek progressed, patents were secured, a name was chosen, marketing materials and packaging were designed, product testing was done, files of paperwork were completed for regulatory requirements to meet FDA standards, and production plans were developed to ensure the highest quality. Proxi-Chek is made in the United States and designed, produced, and packaged at Microcopy’s headquarters in Kennesaw, Ga.

So what problem does Proxi-Chek solve, and what makes it so special? You no longer have to guess while adjusting a crown to fit it just right. The problems caused by guessing and checking and by other marking devices are no more. Overadjusting, hard-to-see marks, and messiness from other marking devices have been eliminated. All the problems caused by an oversized or misshaped crown can now easily be avoided.

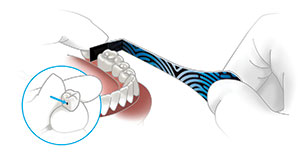

The built-in handle ensures visibility in the area you are marking and provides enough reach so that you do not even have to put your fingers into the patient’s mouth. Plus, it includes a bendable tip to better mark hard-to-reach posterior molars. Additionally, it can mark the crown as well as the adjacent teeth. So, in all, Proxi-Chek is the only device that combines a precise mark of the contact with simplicity to eliminate the guesswork to properly fit a crown. Essentially, it offers a solution to the problems of marking proximity by employing a unique design, simplicity, and affordability, making it more convenient than the traditional ways of fitting a crown.