Bego Implant Systems Overview

|

|

Argon - Rapid

Konus Connection

|

|

|

|

Diameter 3 - 3.5 - 4 - 4.5 - 5 - 6

Height 8 - 9 - 11 - 13 - 15 - 17

|

|

Argon - Sure

Konus Connection

|

|

|

|

Diameter 3 - 3.5 - 4 - 4.5 - 5 - 6

Height 8 - 9 - 11 - 13

|

|

Argon - Sure Short

Konus Connection

|

|

|

|

Diameter 4 - 4.5 - 5 - 6

Height 5.5 - 6.5 - 7.5

|

| For more information Click on the above pictures. |

ARGON Group

The Argon Group head office is located in Bingen am Rhein, Germany. Argon is an international manufacturer of complete dental implant systems designed for the basic, as well as the digital usage of today‘s implantologist. The Argon Group is also a manufacturer/ distributor of allograft materials and accessories needed for basic, as well as advanced Hard- & Soft-Tissue reconstructions. All products from the Argon Group are designed, engineered and produced in Germany and carry the label “Made and Engineered in Germany“. Our products are distributed internationally and are sold solely to clinics, dentists, clinicians and labs for use in the implantology field. Argon also offers and attends various national and international courses and congresses, where clinicians and labs can exchange or gain knowledge and information pertaining to the implantology field.

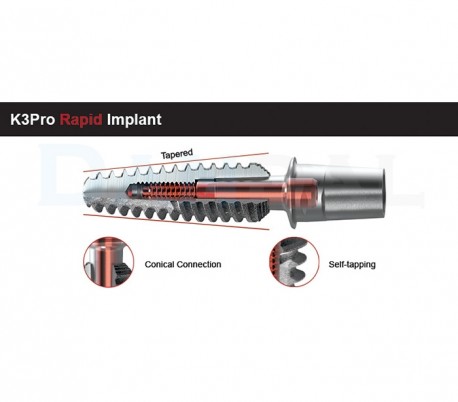

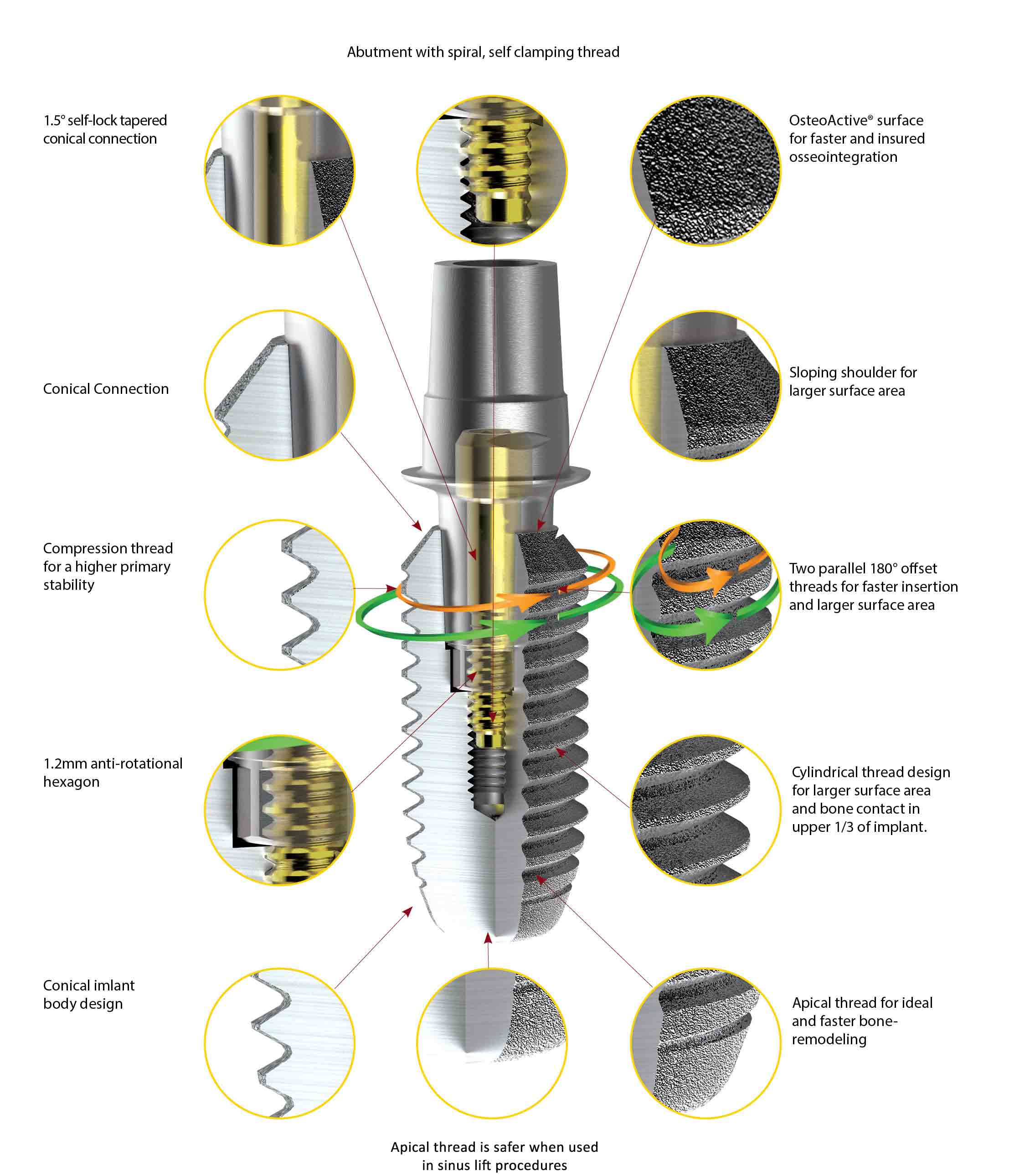

K3Pro Implantat System

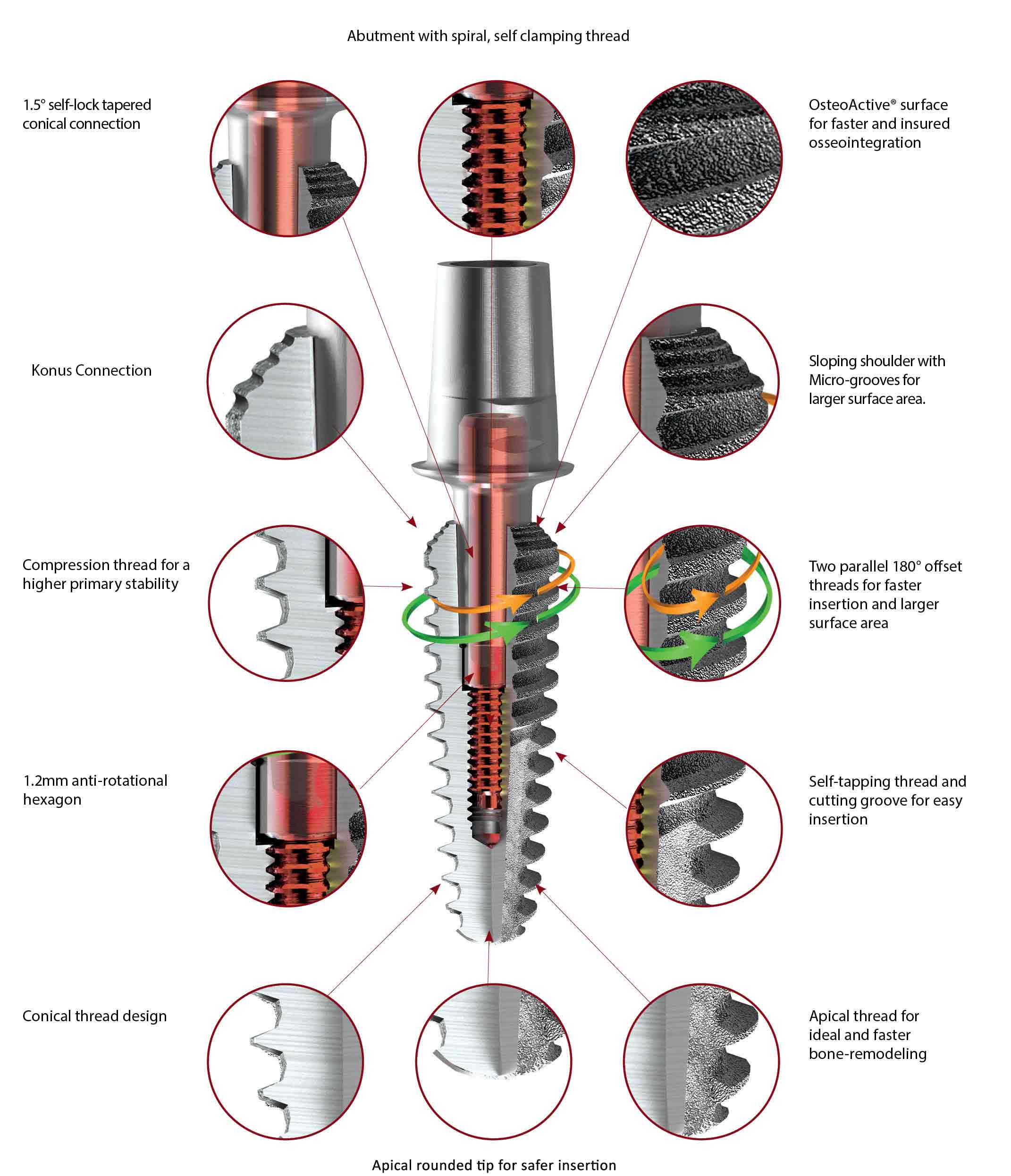

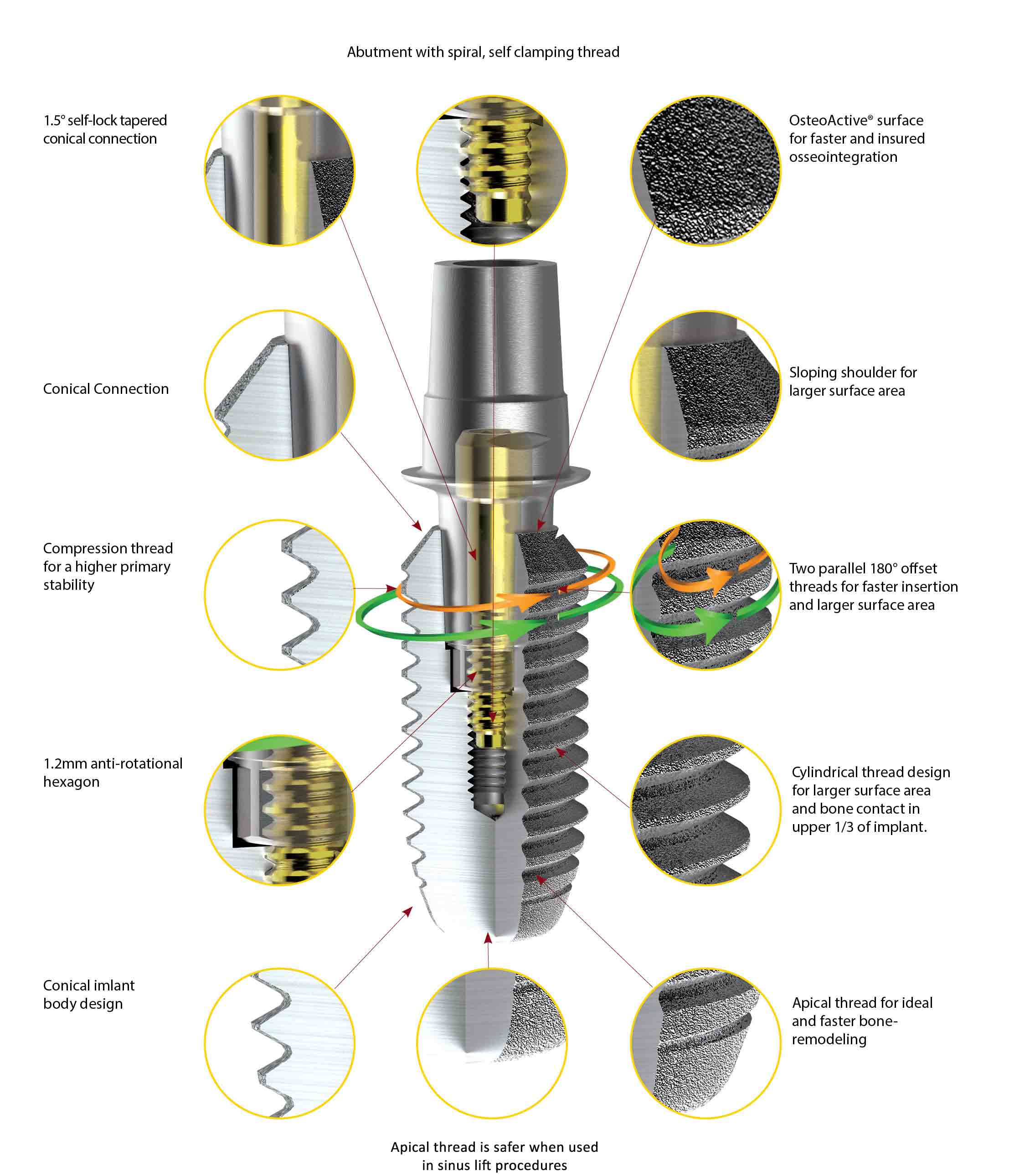

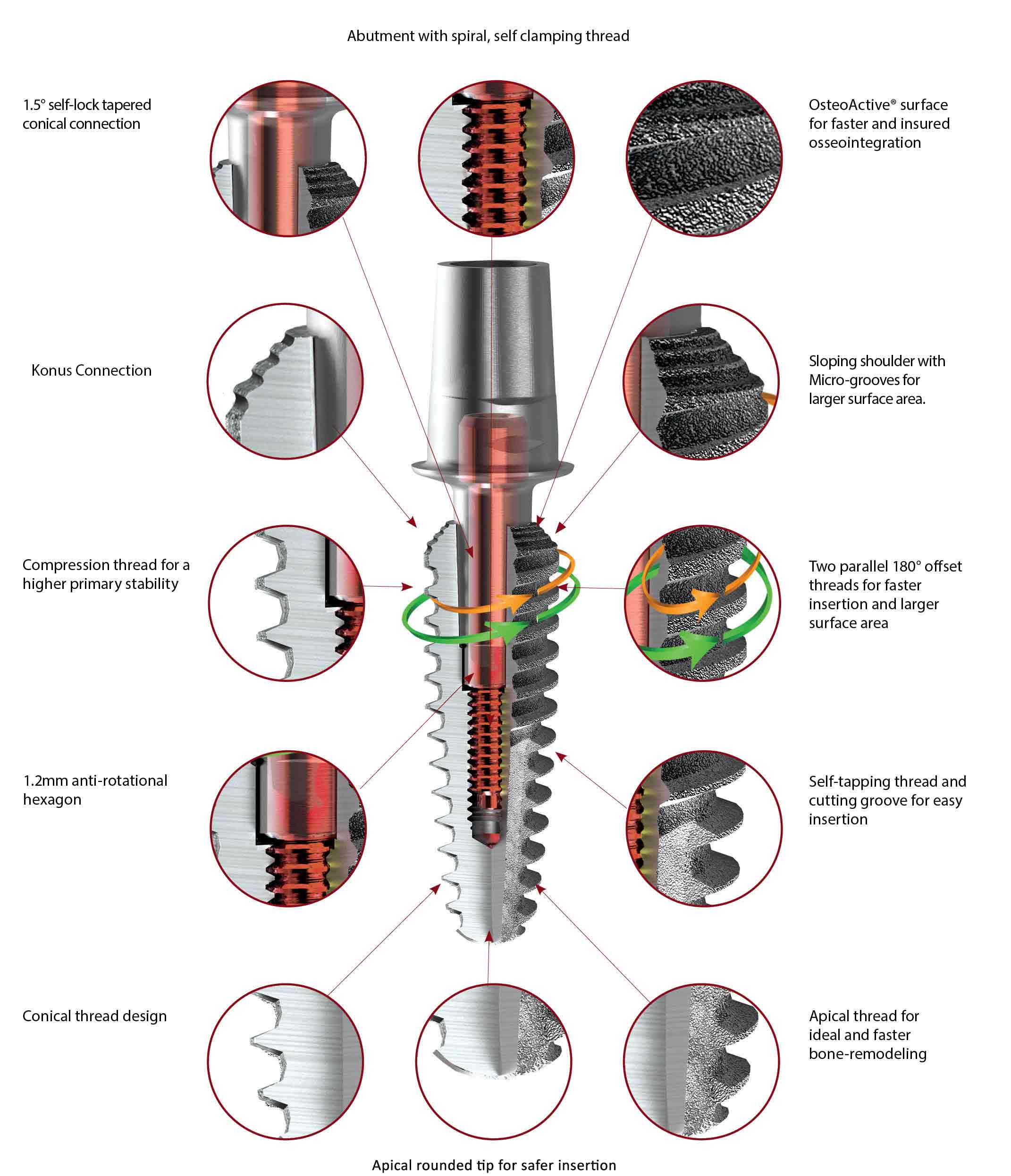

Argons's development and engineering of the K3Pro Implant System includes the broadest selection of prosthetic components on the today‘s market. All components are optimaly suited and matched to the K3Pro Implant System and allow for a large variety of dental treatment possibilites. The K3Pro components and implant system assure for the best possible clinical and esthetic results. The special conical connection allow for a press-fit connection, which allow for abutment placement without screw and hexagon indexing, which allows for 360° placement of the prosthetics. Out implant/abutment connection is like a one-piece implant.

Rapid

Sure

Konus Connection

The development of conical connections in dental implantologie has been reachered and discribed in liturature and publications. This literature decribes that the advantages of the conical connection can only be reached with systems that have a maximum 6° taper. Almost all companies today use the word conical without really have a maximum 6° Morse Taper connection. Especially here, in dental studies, it is shown that with most implant systems without a Morse Taper that we normally have a 1.6mm reduction of bone and corrsponding Papilla around the implant/abutment connection. Also load strains and eventual shoulder /implant breakages were recorded from implants with a flat- or wide conical-connection. Implants with the Morse Taper were unproblematic, whereas here were no breakages or bone loss recorded.

K3Pro Konus

The K3Pro Implant System connects the implant and abutment with a 1.5° (total 3°) taper, which also gives a optimal load dispertion of the abutment into the implant. This allows for optimal product characteristics and loads on smaller implant diameters. K3Pro is at the top of the conical connection market with the 3° taper connection. The connection of the K3Pro is so precise that we even start with 3mm diameter implants that still allow for optimal restorations and chewing abilities within the system. Also the bacterial seal and micro-free movement connection assure optimal esthetic results and avoid bone- and Papilla-loss

In today‘s implantology is the usage of two-piece implant systems more prominent than one-piece implants. This is due to clinical and prosthetic advantages with two-piece implants. By usage of two-piece implant systems; we can say that the periimplant bone height is dependant upon which implant system is used. The influence of the periimplant bone height is dependant from the mechanical and microbiological aspects of the abutment/implant connection. Through the mechanical connection and precision of fit, we also can see screw loosening of abutments and eventually fractures in the area of the implant/abutment connection. The micro-movement of the implant/abutment connection and the therefore increasing micro-gap has been studien and verified by many group studies and clinicians. Zipprich et. al. 2007 describes and verifies this result by simulated chewing and x-ray video recording, that the micro-gap and bacterial influence is prominent with many implant systems. Implant systems with a Morse conical taper should no suggnificant gaps or bacterial influence. In today‘s clinical usage we find extreme variances and differences of implant and abutment connections.

Author: Review department of Dandal.ir

First Release Date: 16/Oct/2017