-

منوی اصلیبستن

-

Dental

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

- Mag

- Help

-

Corporate

-

- Login/ Register

-

منوی اصلیبستن

-

Dental

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

Gloves

-

-

-

- Mag

- Help

-

Corporate

-

- Login/ Register

- Home

- Dental Online Shop - Distributor & Supplier

- CAD/CAM

- CAD/CAM Equipment

- Milling Machine

- DOF - CRAFT 5X 5 Axis Milling Machine

DOF - CRAFT 5X 5 Axis Dental Milling Machine - Dandal

-

In line with the demand of Dandal site customers for credit purchases, Dandal in cooperation with Saman Bank has provided a new service for dental and medical offices and treatment centers, which customers can use a credit card from the site at any time without any cash support.

- More Info

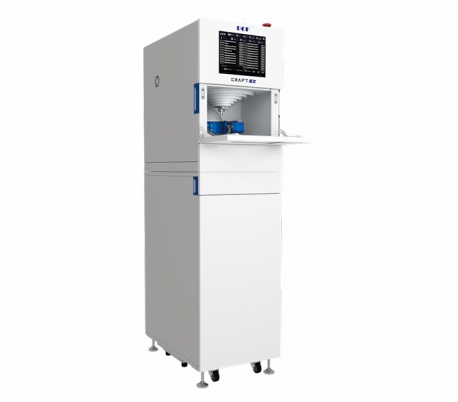

DOF - CRAFT 5X 5 Axis Milling Machine

Out-of-StockPay in installments

Choose your plan:

Current plan: 3Month

Description: 30+3

Down payment: $0.00 (25.00%)

Number of payments: 3

Tax: $0.00

Amount of payment: $0.00

Overpayment: $0.00

Total: $0.00

Current plan: Cash

Description: نقدی

Down payment: $0.00 (0.00%)

Number of payments: 1

Tax: $0.00

Amount of payment: $0.00

Overpayment: $0.00

Total: $0.00

CRAFT 5X

Wet & Dry

Zirconia, wax, PMMA, hybrid ceramic, glass ceramic and titanium are able to be milled

5-Axis

Featuring 5-axis simultaneous machining, ideal for cases with severe undercuts and/or multiple insertion angles.

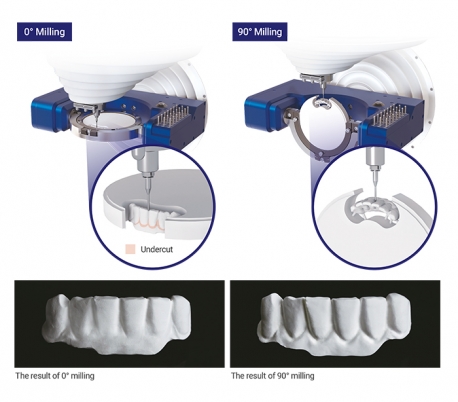

90 Degree Milling

It perfectly reproduces contours of teeth with the 90 degree milling, especially anterior teeth.

One-Step Milling

It mills custom abutments and supra-structures at the same time without the abutment scanning.

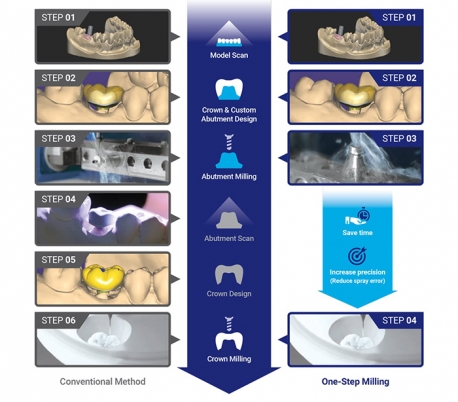

Special Function: One-Step Milling

Everyone thought one-step milling was impossible, but now experience it with CRAFT 5X. CRAFT 5X extends beyond mechanical limitations of conventional milling machines and reproduces your design as it is. One-step milling is complete by producing the abutments and the supra-structures simultaneously with the 5-axis reverse milling method.

While conventional custom abutment production goes through complex stages of designing, milling, and scanning the abutment, one-step milling reduces the production stages by milling the abutment and the supra-structure at the same. Save your time more than one day through milling the abutment during sintering the zirconia bridge. It also improves the accuracy by preventing errors that may occur during scanning.

Special Function: 90 Degree Milling

CRAFT 5X perfectly reproduces contours of teeth in detail with the 90 degree milling. The 90 degree milling provides great satisfaction with innovative milling methods that goes beyond the conventional framework.

CRAFT 5X uses a C-clamp for the 90 degree milling. The externals of teeth can be milled vertically with a block raised to 90 degrees because one side of the C-clamp is open. Delicate milling is possible as it is milling the block at 90 degrees. Tools can get into the undercut areas which cannot be milled at 0 degrees and 180 degrees. In addition, the high-performance motor which precisely controls the milling axes and the rigid frame body made of whole castings enable the error-free 90 degree milling.

The 90 degree milling is very useful when detailed milling is required like interproximal areas, labial textures, and gingiva lines. Especially, anterior teeth where aesthetic aspects are important. It eliminates the cumbersome process of hand trimming zirconia crowns and dramatically reduces working time.

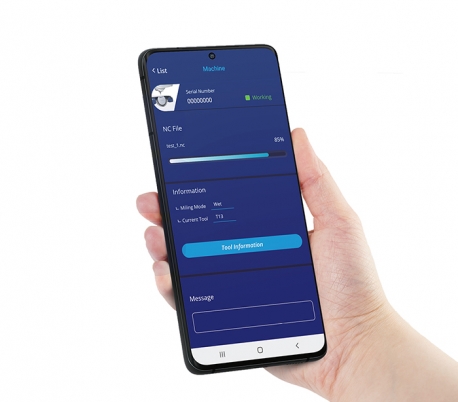

Dental Milling Machine in Your Hand

- Real Time Status and Progress

Monitor the status and progress of your machine in real time with your mobile phone.

- Push Notification

Receive push notifications upon completion of operation or emergency situation for your prompt action.

- Tools Lifetime

View the lifetime of tools in operation, but also all tools in real time.

Wet & Dry Compatible Milling

Choose between a dry type and a wet type depending on the material. In addition, waterproof sealing protection increases machine longevity.

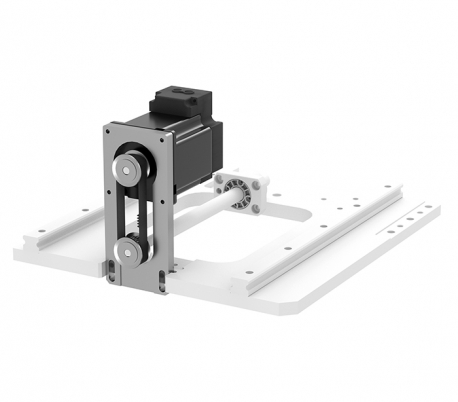

5-Axis Simultaneous Processing

It mills on X, Y, Z axis and rotating blocks and discs 360 degrees in both clockwise and counterclockwise movements. 5-axis milling always allows excellent fits without restrictions on shapes of prostheses.

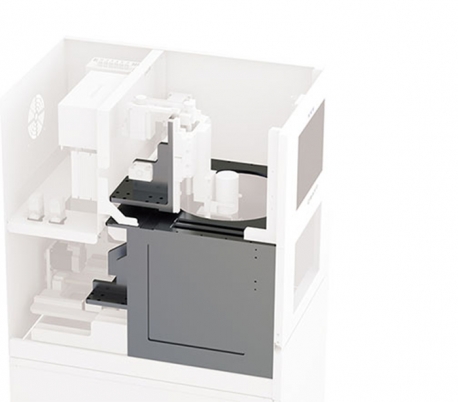

Sturdy & Low-Vibration

Regardless of its compact size, the internal structure of steel components deliver optimal milling speeds with low-vibration for precise milling.

Closed Loop

The change in output due to external disturbance are corrected automatically, where the feedback element is always present, resulting in a more reliable and accurate milling mechanism.

Onboard Computer

A touch screen and a built-in computer are equipped. The machine control software has an intuitive user interface that anyone can easily use.

High Quality Spindle

Durable Jäger spindle, which features up to 100,000 RPM and maximum power of 0.7kw, can mill hard materials stably.

Storage

The table provides a storage area where milling accessories can be stored for easy and quick accessibility.

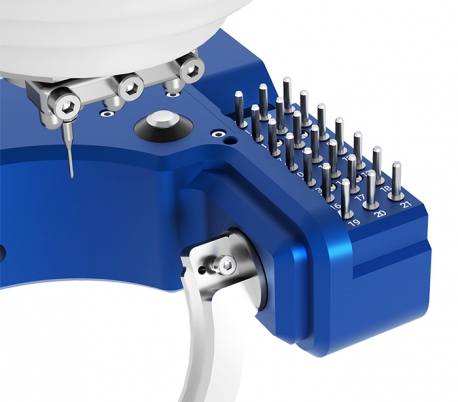

21 Station Automatic Tool Changer

Features an automatic tool changer with up to 21 tool seating capacity. Automatic tool sensor measures tool lengths and automatically detects even the smallest discrepancies.

Product Details

Data sheet

- Company/ Brand

- DOF

- Country

- South Korea

- Application

- Bridge, Inlays, Onlays, Veneer, Abutment (ti-base & metal blanks), Implant supported bridges, Full/Partial denture, Models, Splints, Surgical guides

- Speed of Rotation

- Max. 100000rpm

بیشتر

Data sheet

- Company/ Brand

- DOF

- Country

- South Korea

- Application

- Bridge, Inlays, Onlays, Veneer, Abutment (ti-base & metal blanks), Implant supported bridges, Full/Partial denture, Models, Splints, Surgical guides

- Speed of Rotation

- Max. 100000rpm

Data sheet

- DOF

- South Korea

- Bridge, Inlays, Onlays, Veneer, Abutment (ti-base & metal blanks), Implant supported bridges, Full/Partial denture, Models, Splints, Surgical guides

- Max. 100000rpm

- AC100~240V

- 0.7kW

- Machine: 81kg | Stand: 50kg

- Dry & Wet

- BLDC

- Machine: 440x660x710mm | Stand: 436x660x1000mm

- 5

- 21 Burs Housed - Diameter: 4mm

- Disc, Block

- Zirconium, Wax, PMMA, PEEK, Hybrid Ceramics, Glass Ceramics

Specific References

Leave a comment about this product

Write your review

DOF - CRAFT 5X 5 Axis Milling Machine